Repair and reconstruction

Triple screw pumps

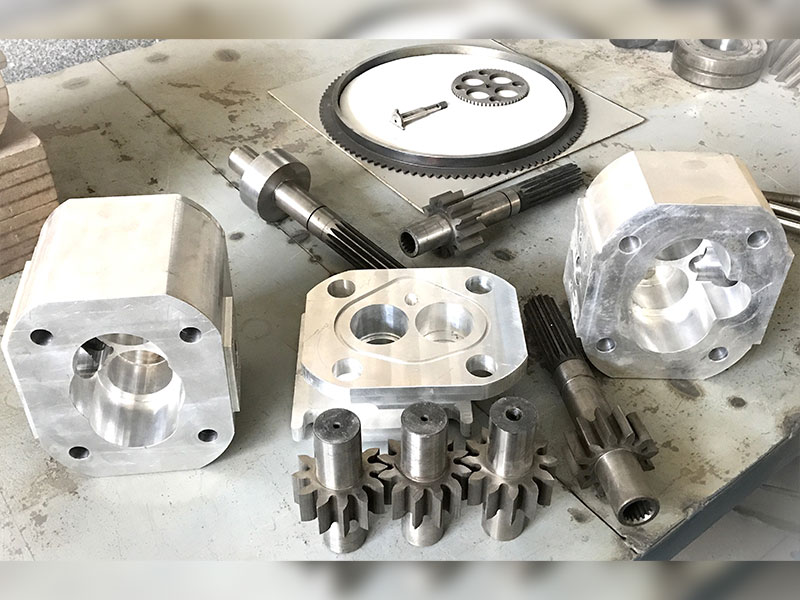

The main damage in Triple screw pumps is related to balance bushings, screw shafts and the main cylinder of the pump. Very high dimensional and geometric accuracy, high quality of raw materials and high mechanical properties are among the characteristics and requirements of the production of parts of this family of pumps. The best and most effective way to reduce the cost of rebuilding and repairing this expensive equipment is to monitor it strictly during operation. Rebuilding screw shafts, renovating the main cylinder, renovating mechanical seal, replacing brass wear parts, and renovating the stuffing box are part of the usual repair and refurbishing processes of this model of screw pumps.

Investigation of the vibrations of the V94.2 turbine liquid fuel triple screw pump

V94.2 turbine liquid fuel triple screw pump

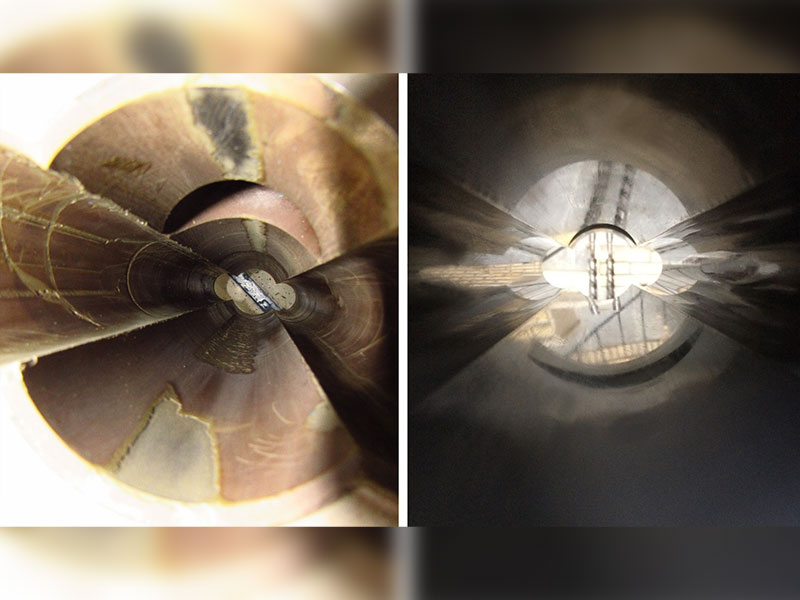

Damaged shafts 2 V94.2 turbine liquid fuel triple screw pump

Interbush V94.2 turbine liquid fuel triple screw pump

Damaged shafts of V94.2 turbine liquid fuel triple screw pump

Assembling the screws and balance bushing of the V94.2 turbine liquid fuel three-piece screw pump

Assembling the screws and the balance of the 3 screw pumps of the V94.2 turbine liquid fuel

Replacement of V94.2 turbo liquid fuel triple screw pump cylinder cover

The main cylinder of the triple screw pump of steam turbine diesel fuel